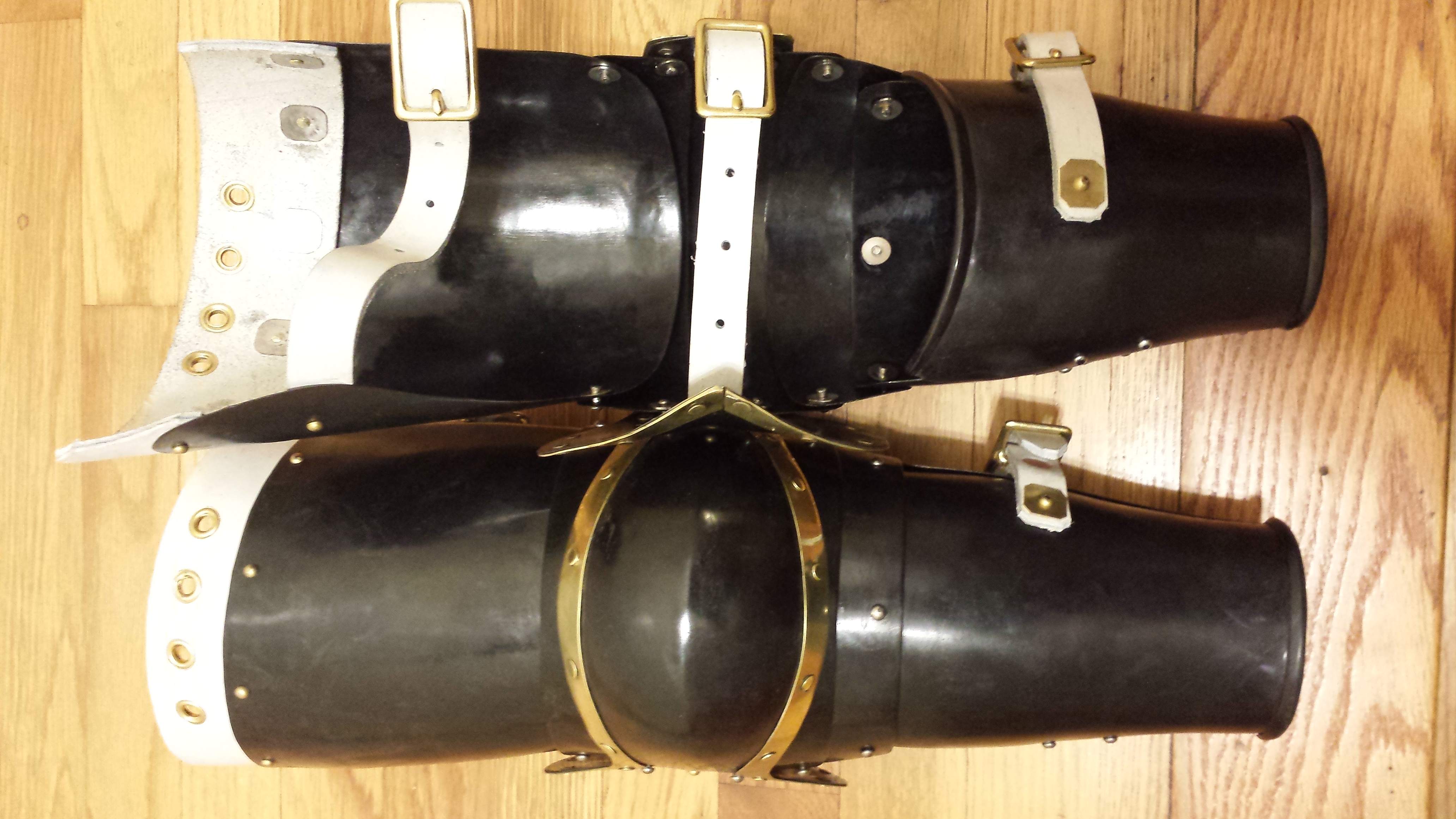

Early 15th Century Italian Arms

Finished January 3, 2015

Early 15th Century Italian Arms

Finished January 3, 2015

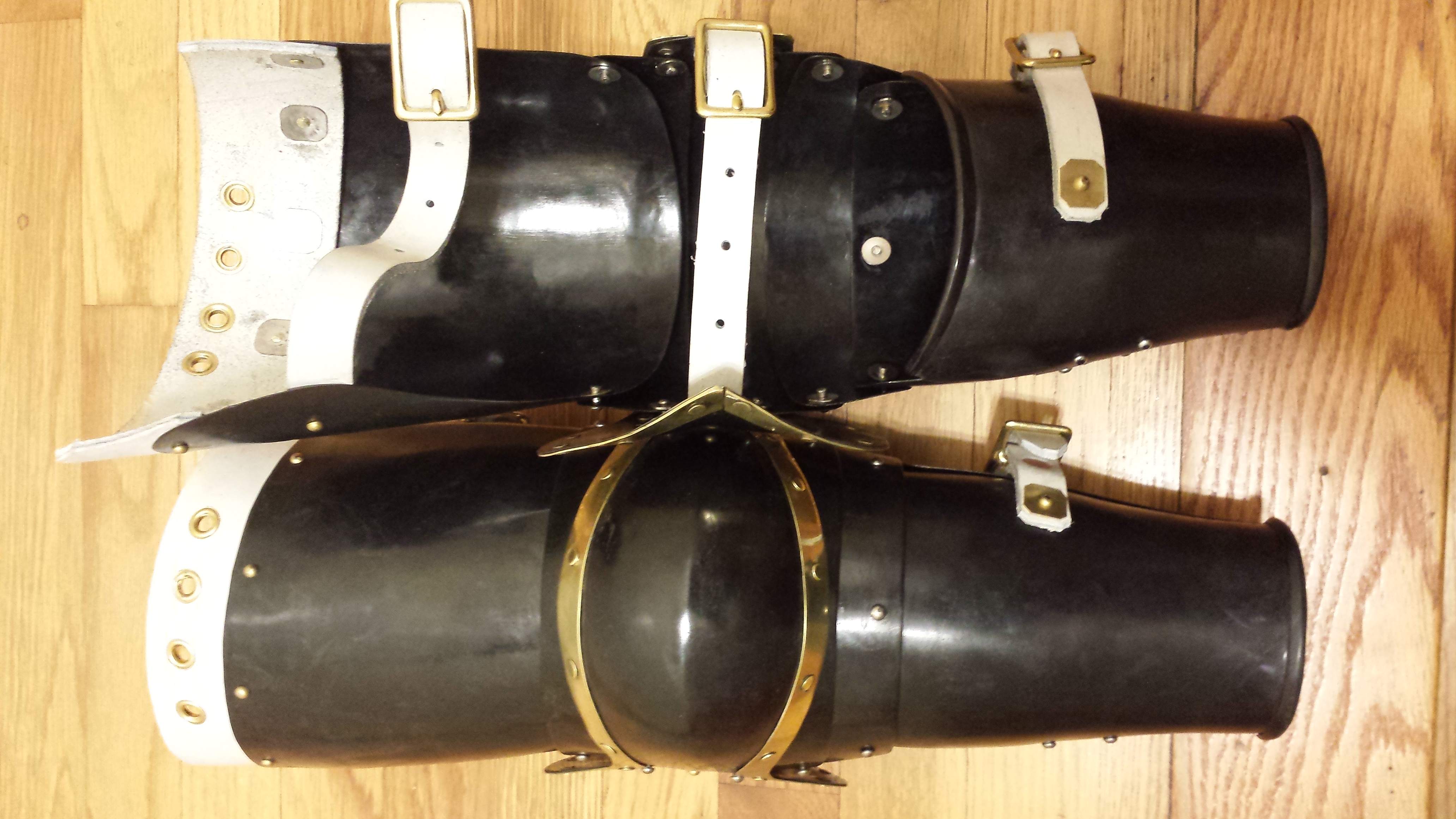

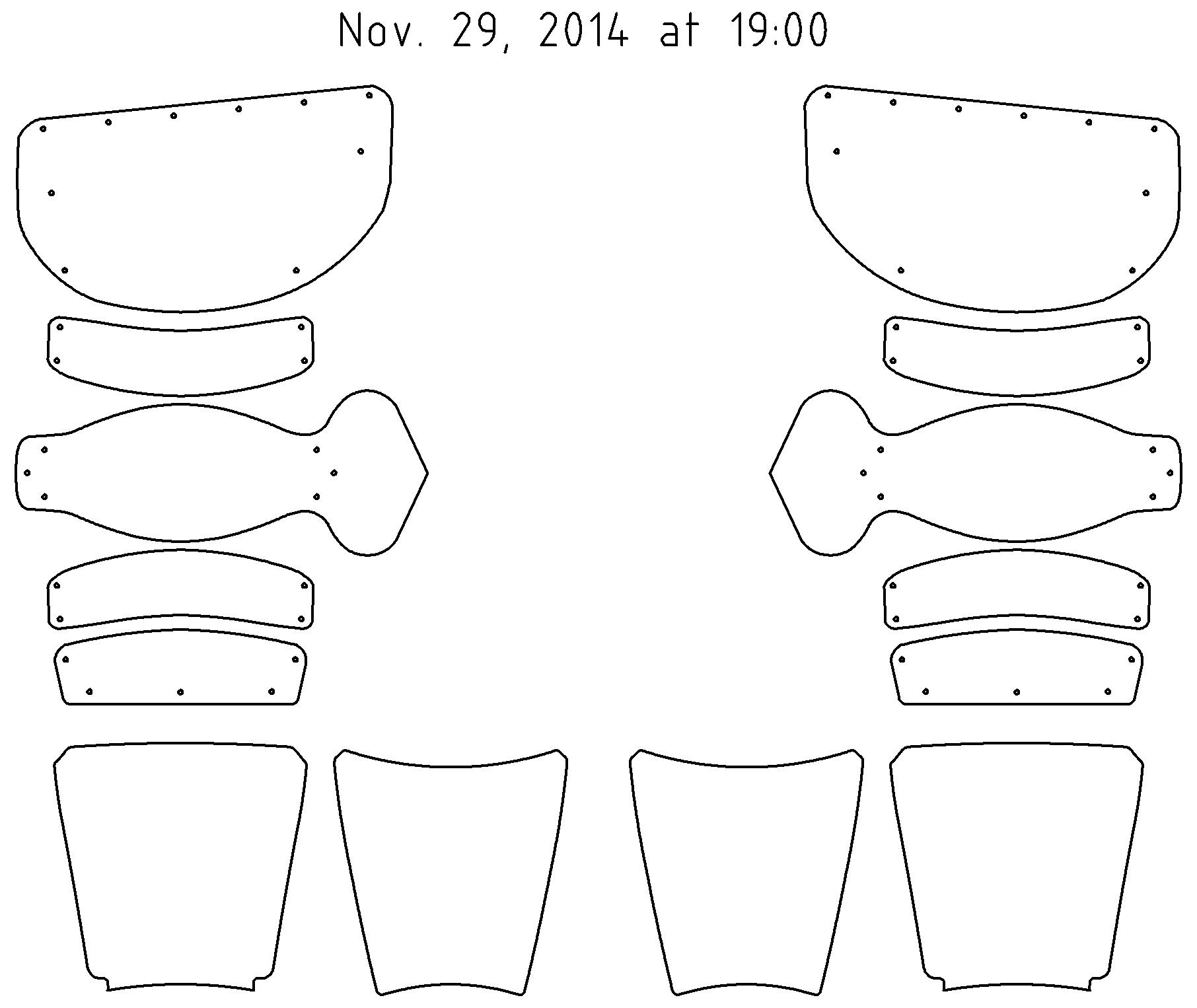

Latest Patterns

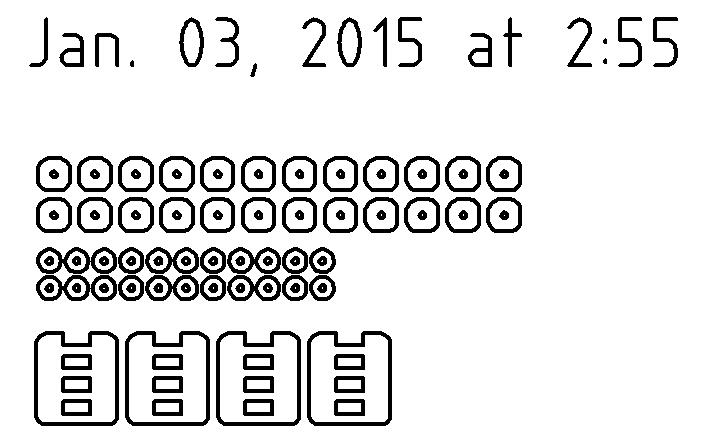

This is the CAD DXF file for the plates. You can use this file to machine cut the metal plates.

arms_early_15thC_20141129.dxf

brass_trim_elbows_20150104.dxf

hardware_20150104.dxf

Finished July 31, 2014

Finished Jan. 27, 2014

Finished March 05, 2013

This is based on the statue of 'Orlando' in Dubrovnik by Bonino of Milan from 1413. A picture of the statue can be seen in The Venetian Empire, 1200-1670 (Men-at-Arms Series, Volume 210) by David Nicolle, Christopher Rothero (Illustrator); 48 pages; Paperback (July 1989) Stackpole Books; ISBN: 0850458994 . Note that I omitted what I believe to have been decorative brass bands.

You can also see a similar effigy on the Tomb of Giovanni Cose of Naples from 1418 in the Louvre. A picture of this appears in "The Sanctuary of the Madonna delle Grazie with notes on the evolution of Italian armour during the 15th century." by James G. Mann printed in "Archaeologia" Journal of The Society of Antiquaries of London 1930 Vol.80 pages 117-142. The picture is Figure 2 on Plate XXIII.

The suit is sized for someone between who's height is 5'8"/172cm to 6'2"/188cm and who's weight is 200lbs./91kg to 225lbs./102Kg.

Older Work

Finished April 11, 2000

Pair of arms 1050 Carbon Steel 18ga. Heat treated (quenched at

1500F and Tempered to 600F) (shown 1st)

Note that the turning pins and the interlocking tabs on the vambrace

are not correct for 15th century Italian arm harnesses. The

turning

pins were added at the buyers request, the correct way of closing the

vambrace

is a single strap and buckle. The interlocking tabs were added as

reenforcements

for SCA rattan combat.

Finished Jan. 2000

Pair of arms 1050 Carbon Steel 18ga. and 20ga. Heat

treated

(quenched at 1500F and Tempered to 600F) (left arm shown 2nd)

Left arm 304 Stainless Steel 18ga. and 20ga.

Right arm 304 Stainless Steel 16ga. and 18ga.

Finished April 1999

Right arm 304 Stainless Steel 18ga. and 20ga. (for tournaments)

Finished Sept. 1999

Pair of arms 1050 Carbon Steel 18ga. and 20ga. Heat treated (quenched at 1500F and Tempered to 600F) (left arm shown 2nd)

Finished Jan. 2000

Pair of arms 1050 Carbon Steel 18ga. Heat treated (quenched at

1500F and Tempered to 600F) (shown 1st)

Note that the turning pins and the interlocking tabs on the vambrace

are not correct for 15th century Italian arm harnesses. The

turning

pins were added at the buyers request, the correct way of closing the

vambrace

is a single strap and buckle. The interlocking tabs were added as

reenforcements

for SCA rattan combat.

Finished April 11, 2000

Updated Patterns on April 11,2000

Patterns

I would build these arms in the following order:

1) cut out the plates

2) punch any holes which are on the patterns

3) finish the plate edges and corners

4) Roll the edges of both the vambrace halves marked --ROLL--

on the pattern

5) Dish couter/"elbow cop" and shape the wing. Raise/Shape the

front of the vambrace. Shape the other plates.

6) Fine tune the articulation. Optional: Cut slots for

the sliding rivets connecting the vambrace to the outer lane.

7) Polish the plates

8) Assemble the arms. Add the hinge for the vambrace. Add catch

tabs for the vambrace.

9) Add the straps. Optional: Add spring pins for

the vambrace.

Copyright 2015 Craig W. Nadler All rights reserved